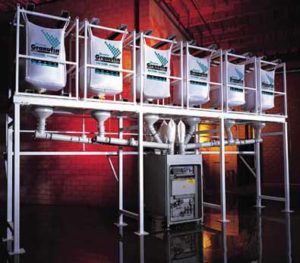

The GRANUMAT™ automatic dosing system is a modular machine that enables the easy, clean and accurate coloring of concrete in a wide spectrum of shades using free flowing GRANUFIN™ micro granules. We offer a wide range of GRANUMAT™ dosing units to meet your needs. Complete systems are configured to match production demands, color complexity and location constraints. We have also developed dedicated system controls that are easy to use.

Ancillary equipment includes a dust extraction unit and holding hopper cyclone.

Efficient

Our GRANUMAT™ units can be configured for up to three batching plants working in parallel – with each of these supplying four concrete mixers simultaneously.

Flexible

All GRANUMAT™ units are capable of storing more than 1,000 recipes.

We offer a wide range of GRANUMAT™ dosing units to meet your needs. Complete systems are configured to match production demands, color complexity and location constraints. We have developed dedicated system controls that are easy to use. Ancillary equipment includes a dust extraction unit and holding hopper cyclone.

How to select your dosing system

How to select your dosing system

Number of colors – our standard GRANUMAT™ system has up to eight colors. We can provide customized systems for up to 16 colors.

Required accuracy level – the available dosing time and the smallest amount to be weighed will determine the system type.

Number of batching plants, production cycle and color requirement – production demands and the complexity of colored products (such as brindled color) determine the number of conveying vessels and cyclones required. One conveying vessel is required per batching plant and up to four cyclones per mixer.

Space and material handling – factors to consider include available footprint and height restrictions, along with the big bag handling method (forklift or crane). The number of primary colors you are using will also impact on the area needed for the GRANUMAT™ system.

Distance from mixers – the standard distance between the GRANUMAT™ installation and mixers is up to 70m (230ft). We can, however, provide a customized solution that extends this distance to 100m (330ft).

Talk to us about your needs. We’ll help you find the best system for your operations.

Talk to us about your needs. We’ll help you find the best system for your operations.

System choice

Dosing system:

- GRANUMAT™ Color Synthesizer

- GRANUMAT™ Multicolor

- GRANUMAT™ Shorty

- GRANUMAT™ Maxi

- GRANUMAT™ Babymat

- GRANUMAT™ Micro

- GRANUMAT™ Colorsmart

- GRANUMAT™ Smarty

- GRANUMAT™ Microsmarty

System controls:

- GRANUMAT™ WinCC PC-Control

- GRANUMAT™ PlC Control with Touch Panel

Ancillary equipment:

- Vacuum Conveyor

- Holding Hopper Cyclone

- Dust extraction Unit