Aqueous pigment dispersions are nothing new at Davis Colors™. In fact, we have been formulating liquid-based pigments since 1960 for paint and coating manufacturers. But we waited until now to introduce Hydrotint®, our new aqueous pigment dispersions especially formulated for colored concrete. That’s because Davis Colors™ is committed to “Setting the Standard in Concrete Colors™”. A liquid color had to prove itself as reliable and effective as our dry pigments before we could put the Davis Colors™ name on it.

To develop Hydrotint®, we drew upon our years of experience and worldwide resources. We began supplying liquid pigments to a select group of concrete producers in 1992. Listening to their comments and understanding how liquid colors effect concrete costs and efficiency, we were able to improve upon existing formulations. The result is a state-of-the-art liquid color.

Formulated for Concrete

Hydrotint® is a slurry of high-quality iron oxide pigments, special dispersants and stabilizers in water. It is formulated especially for use in automated dispensing equipment for plant-produced, integrally colored concrete products.

Proven Ingredients

Hydrotint® slurries are made from the same synthetic iron oxides that comply with ASTM C979 and Davis has processed for almost 50 years.

Ready to Flow

Hydrotint® slurries have been carefully formulated for high pigment content and improved flowability vs. other company’s slurries to provide accurate metering and faster production cycles.

Stable in Storage

Advanced formulation allows up to a two-year shelf life without hard settlement. Normal agitation before use is all that’s needed.

A Shade for all Uses

Four primary colors are standard: Black, Yellow, Light Red and Medium Red. These can be combined on-site by the customer using dispensing equipment to make a wide spectrum of popular colors. Or, Davis can pre-blend them to create a single color to simplify use and increase metering accuracy. We can also fine-tune primary slurry colors for special requirements or custom matches.

Consistant Color

Color tolerance is kept within +/- 0.7%. Pigment particles are milled to optimum size and are high-shear dispersed to assure rapid dispersion into the concrete mix and full color development. Rigorous quality controls assure uniformity from batch-to-batch and year-to-year.

High Pigment Content

High Pigment Content

High pigment solids content minimizes water component and assures compatibility with typical water-cement ratios.

Liquid you can rely on

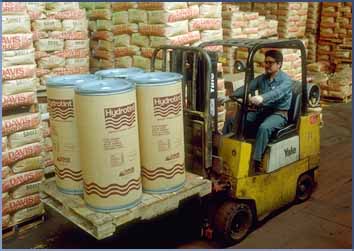

Hydrotint® is manufactured by Davis Colors, the leading pigment supplier to the concrete industry. We offer automated dispensing equipment, installation and start-up assistance, color formulations to match your product standards or custom color requirements, and ongoing technical and marketing support. Nobody knows concrete colors better than Davis Colors™. Hydrotint® is available in 600 pound fiber drums, re-useable 265 gallon tote bins or disposable 220 gallon corrugated bins.